Many buyers want to get the best deal when buying a foam roller from an OEM factory. Good sourcing begins with clear product needs. Careful research helps find good suppliers. Good negotiation skills can get better prices and quality. Smart choices help buyers do better in the market.

Key Takeaways

- Decide what you need before you buy. Think about size, material, and design. This helps you get the right price. It also helps you avoid mistakes.

- Look for OEM factories that have lots of experience. Make sure they have good certifications. They should answer your questions quickly. This gives you better quality and trust.

- Try samples before you make a big order. Check if the foam is firm. Feel the texture. Make sure it will last. This saves you time and money.

- Buy in large amounts to get lower prices. Ask for extra things like free logo printing. You can also ask for faster shipping. These things add value.

- Order from the same factory often. Talk to them clearly. This helps you get better deals. It also helps you get good quality every time.

Know Your Needs

Set Specs

Buyers need to know what they want before buying. They should decide the length, diameter, and color of the foam roller. Some people like a smooth surface. Others want a textured one for more muscle relief. The material is important too. EVA foam and polypropylene are strong and last long. Buyers must pick between a hollow core or a solid one. Custom branding or special packaging can help sell more in stores.

Tip: Clear details help factories give the right price and avoid mistakes.

Order Size

How many you order changes the price and choices. Factories give better prices for big orders. Small minimum order quantities can mean less choice or higher prices. Buyers should guess how many they need and how much space they have. Planning for more sales later can help get better deals and steady supply.

- Small orders: Cost more for each, fewer choices

- Large orders: Cost less for each, more design and branding options

Quality Level

Quality rules help make a good product. Buyers should ask for test results and how the foam performs. Industry rules like ASTM D3574 help test foam for density and strength. The table below shows what each test means:

| Specification / Metric | Description / Relevance to Foam Roller Quality |

|---|---|

| ASTM D3574 | Main rule for testing flexible polyurethane foam |

| Density | Tells how heavy the foam is and how strong it is |

| Indentation Force Deflection (IFD) | Shows how firm and soft the foam is |

| Compression Force Deflection (CFD) | Checks how well foam resists being pressed down |

| Compression Sets | Shows if foam goes back to shape after being pressed |

| Tensile Strength | Tells how much pulling the foam can take |

| Tear Strength | Shows how well foam resists tearing |

| Resilience | Tells if foam bounces back after being squished |

| Fatigue Tests | Checks if foam lasts after many uses |

| Air Flow | Shows if air moves through for comfort |

| Heat Aging | Tests if foam stays good in heat |

| Recovery Test | Checks if foam returns to shape after use |

| Flammability | Safety rule for products people use |

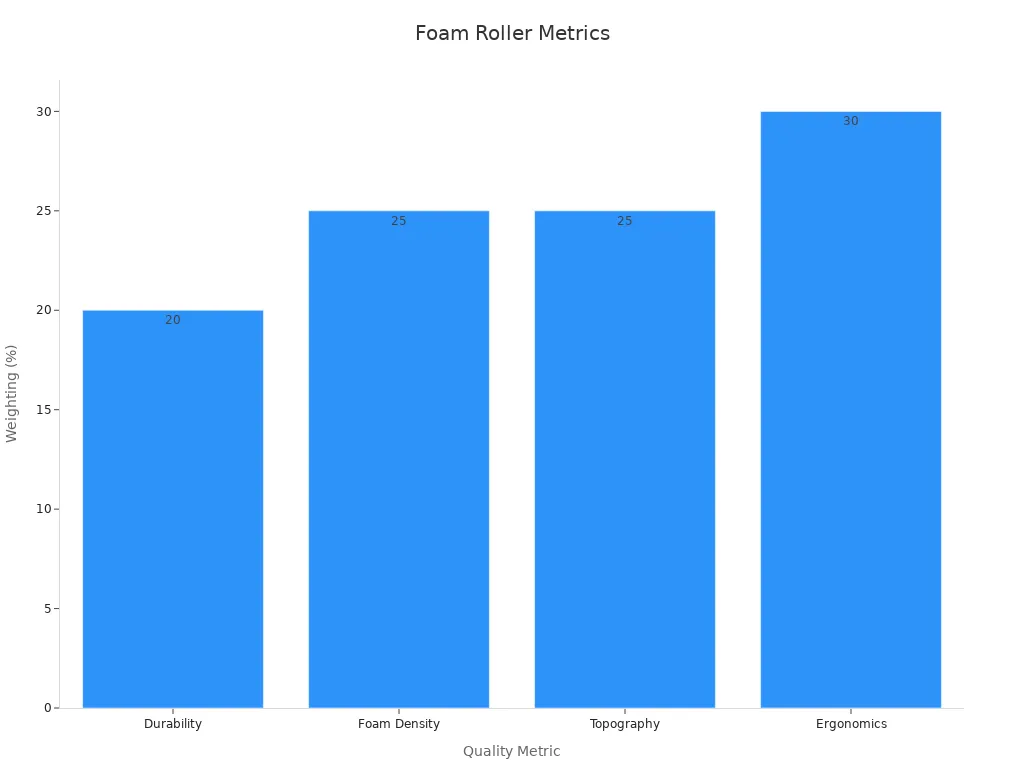

Buyers should also check how long the foam lasts, its density, shape, and how easy it is to use. The chart below shows why each part matters:

A good foam roller has a strong core, different foam layers, and a bumpy surface. These things help you control it, feel comfortable, and use it longer.

Find OEM Factories

Research Options

Buyers should look for OEM factories that make foam rollers. Many top factories are in China and Taiwan. These places supply big fitness brands. Buyers can search online, go to trade shows, or use industry lists to find factories. They should pick factories with clear catalogs and quick replies. Good factories answer questions fast and give lots of details about their products.

Tip: Ask for a list of brands the factory supplies. This helps you know if the factory is trusted.

Compare Experience

Experience is important when making foam rollers. Factories with many years in business can handle big orders and fix problems. Chinese and Taiwanese factories often have lots of experience and good machines. Some factories have their own mold workshops. This helps them make custom designs and change things quickly. Buyers should check how long each factory has worked and what products they make. Factories that can customize well help brands be different from others.

- Factories with their own mold workshops give:

- Faster samples

- More design choices

- Better quality checks

Check Certifications

Certifications show a factory follows the rules. Buyers should ask for ISO 9001 for quality or SGS reports for safety. Factories with these papers follow strict rules and make safer products. Some factories also have green certificates. This means they use safe materials and care about nature. Buyers should always ask for proof of these certificates before buying.

| Certification | What It Means |

|---|---|

| ISO 9001 | Quality management system |

| SGS | Product safety testing |

| RoHS | Restricts hazardous substances |

| CE | Meets EU safety standards |

Foam Roller Quality

Material Choice

Factories use different foams to make rollers. Polyethylene foam is firm and strong. EVA foam feels softer and does not crack easily. Some brands use polypropylene for extra strength. The material changes how the roller feels and how long it lasts.

Many factories now have antimicrobial foam. This foam helps stop germs and mold from growing. It keeps the roller cleaner and safer to use. Buyers can also choose how firm the roller is. Soft rollers are good for beginners. Firm rollers help athletes with muscle relief.

| Foam Type | Firmness Level | Durability | Special Features |

|---|---|---|---|

| Polyethylene | High | High | Good for heavy use |

| EVA | Medium | Medium | Soft feel, resists wear |

| Polypropylene | Very High | Very High | Extra strength |

| Antimicrobial | Varies | High | Stops bacteria growth |

Tip: Buyers should pick the foam type for their customers. Athletes may want a firmer roller. Beginners may like a softer one.

Manufacturing Process

Factories use machines to shape and cut foam rollers. These machines help make each roller the same size. Tight controls mean every roller meets the same rules. This helps stop mistakes and keeps quality high.

Many factories buy new machines and tools. Automation makes work faster and more steady. These upgrades help rollers last longer and work better. New materials also help rollers resist damage and stay stable. Factories can make special rollers for sports or medical needs.

- Semiconductor wafer fabrication needs very exact rollers.

- Strong quality checks make sure rollers meet high standards.

- Automated machines keep quality steady and lower mistakes.

- Better materials help rollers last longer and work well.

- Custom rollers help meet special customer needs.

Test Samples

Buyers should ask for test samples before big orders. Samples show the real quality of the roller. They help buyers check firmness, texture, and strength. Testing samples shows if the roller is safe and comfortable.

Factories test for density, strength, and recovery. These tests show if the roller will last a long time. Buyers can use test results to compare factories. A good sample helps buyers trust the final product.

Note: Testing samples saves money and time by finding problems early.

Negotiate Price

Bulk Deals

Factories give better prices if you buy more. Big orders help factories plan and save money. Buyers should ask for lower prices with bigger orders. For example, a factory may charge less per roller if you buy 1,000 instead of 500. Buyers can ask for a price chart that shows discounts for bigger orders.

| Order Quantity | Price per Unit | Savings (%) |

|---|---|---|

| 500 | $4.50 | 0% |

| 1,000 | $4.35 | 3% |

| 5,000 | $3.90 | 10% |

Tip: Buyers can team up with other companies to order together. This helps everyone get a lower price.

Factories might also give free samples or extra rollers for big orders. Buyers should ask about these deals when talking with factories.

Value Services

Price matters, but extra services are important too. Some factories give free logo printing or custom boxes for big orders. They may also ship faster. These extras help brands look special. Buyers should make a list of the services they want before talking to factories.

- Free logo printing

- Custom packaging design

- Faster production times

- Quality inspection reports

- Flexible storage options

Buyers should see if the extra services are worth the price. Sometimes, paying a little more gives you more services and saves money later.

Note: Extra services can help a brand grow and make customers trust you.

Payment Terms

Payment rules change how money moves and risk. Factories may want a deposit before making the rollers. The rest is paid before shipping. Buyers should try to get better rules, like a smaller deposit or more time to pay.

Common payment rules are:

- 30% deposit, 70% before shipment

- 50% deposit, 50% after delivery

- Net 30 or Net 60 (pay 30 or 60 days after delivery)

A clear payment plan helps both sides avoid problems. Buyers should always get payment rules in writing. They should also ask if the factory takes safe payments, like letters of credit or escrow.

Tip: Good payment rules help a business grow by saving cash for other things.

Hidden Costs

Shipping Fees

Shipping fees can surprise many buyers. Factories often quote prices that do not include delivery. The cost to ship foam rollers depends on size, weight, and destination. Air freight moves products faster but costs more. Sea freight takes longer but saves money for large orders. Some factories offer FOB (Free On Board) pricing, which covers delivery to the port. Others use CIF (Cost, Insurance, and Freight), which includes shipping and insurance to the buyer’s port.

Tip: Buyers should always ask if the price includes shipping. They should compare shipping methods and get quotes from different freight companies.

A simple table helps buyers see the difference:

| Shipping Method | Speed | Cost | Best For |

|---|---|---|---|

| Air Freight | Fast | High | Small urgent orders |

| Sea Freight | Slow | Low | Large bulk orders |

Taxes & Duties

Taxes and import duties add extra costs. Each country sets its own rules for foam roller imports. Customs may charge VAT, GST, or other taxes. Some countries have free trade agreements that lower these fees. Buyers must check the HS code for foam rollers to know the exact tax rate.

- Import taxes can change each year.

- Customs brokers can help with paperwork.

- Unpaid taxes can delay delivery.

Note: Smart buyers plan for taxes in their budget. They ask the factory for help with customs documents.

Customization Costs

Custom designs make a brand stand out but can raise costs. Factories may charge for new molds, special colors, or unique packaging. Mold fees often cost hundreds of dollars. Custom printing or embossing adds to the price per unit.

- Mold fee: One-time cost for new shapes

- Printing: Extra charge for logos or patterns

- Packaging: Higher cost for custom boxes

Buyers should ask for a full list of customization fees before placing an order. This helps avoid surprises and keeps the project on budget.

Customization can boost sales, but buyers must weigh the extra cost against the benefits.

Build Partnerships

Ongoing Orders

Working closely with OEM factories helps buyers get a steady supply. Buyers who order often show they are serious. Factories usually help these buyers first when they are busy. They might let them try new products or materials before others. Regular orders help both sides plan better. Factories can set their work schedules. Buyers do not run out of stock.

Tip: Buyers should make a simple order calendar. This lets everyone know when new orders will come.

Better Terms

Good relationships can lead to better deals. Factories may give lower prices to buyers who order again and again. They might let buyers pay later or ship faster. Some factories give free upgrades, like better packaging or extra checks for quality. Buyers who trust their factories can ask for these extras.

The table below shows what loyal buyers might get:

| Partnership Level | Price Discount | Payment Flexibility | Extra Services |

|---|---|---|---|

| New Buyer | 0% | Standard | None |

| Repeat Buyer | 5% | Extended terms | Free logo printing |

| Long-term Partner | 10% | Net 60 days | Priority production |

Note: Buyers should always ask about loyalty programs or special deals for regular customers.

Consistent Quality

Partnerships help keep the product quality high. Factories learn what each buyer wants over time. They change how they work to meet these needs. Buyers can ask for regular reports or set up checks. Giving feedback helps factories fix small problems early.

- Talking often builds trust.

- Quality checks keep products good.

- Feedback helps make products better.

Buyers who build strong partnerships see fewer problems and better reviews. Good quality helps brands grow and keeps customers happy.

Getting the right foam roller from an OEM factory needs good planning. Buyers must know what they want and check how much experience each factory has. They should also try out samples to see if they are good. Buyers can talk with factories to get lower prices and look out for extra costs. Making good relationships with factories helps buyers get better deals and good products every time. If buyers follow these steps, they can get the best foam rollers for less money. Start making smart choices when you buy today.

FAQ

How can buyers verify a foam roller factory’s reliability?

Buyers need to look for certifications and read reviews. They should ask the factory for references from other customers. Visiting the factory or having a video call helps check if it is real. Good factories share clear papers and answer questions fast.

What is the typical lead time for OEM foam roller orders?

Lead times are usually between 20 and 45 days. The time changes based on how many you order and if you want special designs. How busy the factory is also matters. Buyers should always check the timeline before they order.

Can factories customize foam rollers for branding?

Most OEM factories let you pick colors, logos, and packaging. Some factories have their own mold workshops for special shapes. Buyers should talk about branding early so there are no delays.

What should buyers do if they receive defective foam rollers?

Buyers need to tell the factory right away. They should send photos and explain what is wrong. Most good factories will give replacements or refunds if there is a real problem.