Smart ways to manage supply chains in fitness equipment involve using technology, building strength, and meeting new customer needs through effective supply chain management. The global fitness equipment market is projected to be worth USD 18.91 billion in 2025, with the Asia-Pacific region expected to grow the fastest.

| Metric/Aspect | Value/Projection |

|---|---|

| Market size in 2024 | USD 17.92 billion |

| Market size in 2025 | USD 18.91 billion |

| CAGR (2025-2034) | 5.5% |

| North America revenue share | Over 39% |

| Asia-Pacific growth trend | Fastest-growing region |

Advanced supply chain management leverages AI and IoT to optimize delivery routes, improve warehouse accuracy, and provide real-time tracking. These technologies enable companies to move fitness equipment safely and efficiently. The gym equipment supply chain is embracing digital transformation to stay competitive in a rapidly evolving fitness market.

- IoT offers real-time tracking and asset monitoring throughout the supply chain.

- AI systems predict issues, enhance delivery efficiency, and support sustainability efforts in fitness equipment supply chain management.

Key Takeaways

- Companies use AI, IoT, and blockchain to watch shipments. These tools help spot problems early and keep information safe in fitness equipment supply chains.

- Having many suppliers and flexible shipping plans lowers risks. This helps with delays, price changes, and political problems.

- Real-time tracking and smart logistics like cross-docking help things move faster. Last-mile delivery also makes customers happy and saves money.

- Digital payment platforms and buying in bulk save money. They make payments faster and help global business run smoothly.

- Using green practices and strong supplier partnerships makes supply chains stronger. This protects the environment and helps companies succeed for a long time.

Supply Chain Management Trends

Globalization and Technology

Globalization is changing the fitness equipment industry in 2025. Companies get materials and products from many countries. This brings good things and some problems. Steel prices went up by 15% in 2024. This makes it harder to make products and earn money. New tariffs and rules, mostly from China, can slow things down and make imports cost more. Shipping is slower because of crowded ports, higher fuel prices, and worker strikes. Shipping delays have gone up by 30%. Some suppliers have money problems. About 10% of them might go bankrupt because of inflation and high demand.

Companies can avoid big problems if they use more than one supplier and shipping route. They also keep extra inventory and check if suppliers are doing well. These steps can cut disruptions by half. Real-time tracking helps keep supply steady and business running.

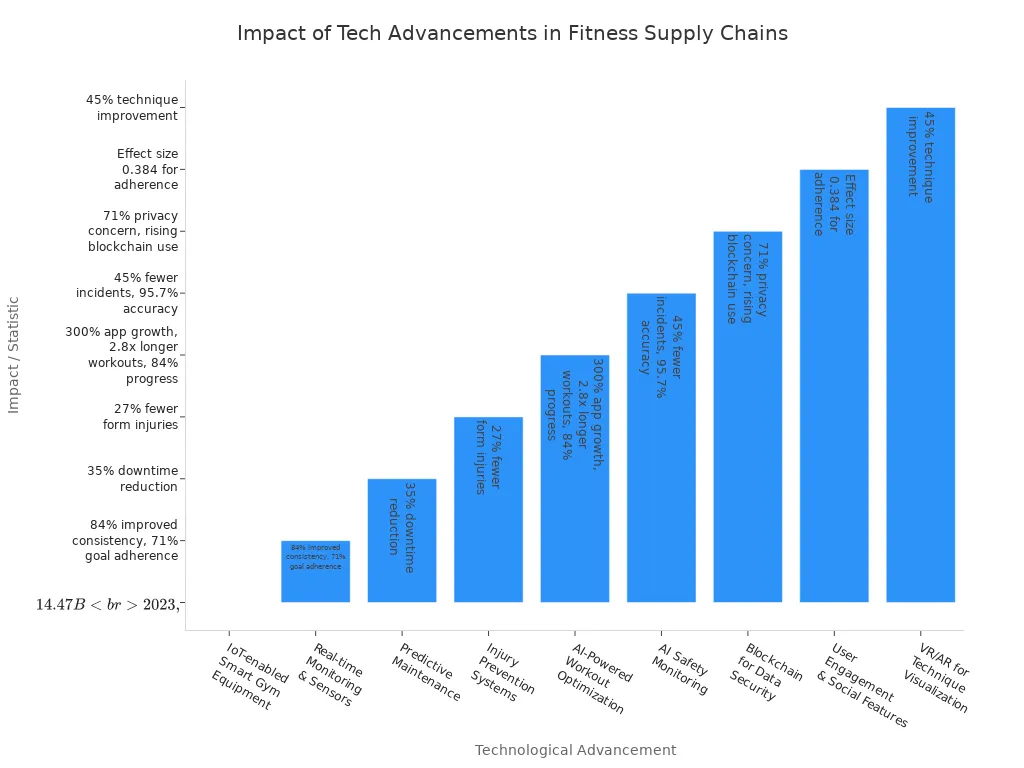

Technology is very important in supply chain management today. Companies use AI, IoT, and blockchain to work better. The table below shows the top technology changes in fitness equipment supply chains:

| Technological Advancement | Impact/Statistic | Source/Notes |

|---|---|---|

| IoT-enabled Smart Gym Equipment | Global home fitness equipment market valued at $14.47B in 2023; projected to reach $21.84B by 2032 (CAGR 4.7%) | Market analysis |

| Real-time Monitoring & Sensors | 84% of gym members improved workout consistency; 71% better adherence to fitness goals | Facility reports |

| Predictive Maintenance | Equipment downtime reduced by up to 35% compared to traditional schedules | Operational data |

| Injury Prevention Systems | 27% decrease in form-related injuries through real-time movement analysis and corrective feedback | Safety studies |

| AI-Powered Workout Optimization | 300% growth in AI fitness app adoption since 2020; users maintain workouts 2.8x longer; 84% report improved progress | User studies |

| AI Safety Monitoring | 45% reduction in incidents with AI-based safety systems; CNN movement detection accuracy 95.7% | AI safety research |

| Blockchain for Data Security | 71% of users concerned about data privacy; blockchain adoption increasing for secure fitness data | Market survey |

| User Engagement & Social Features | Social support in digital platforms correlates with exercise adherence (effect size 0.384) | Behavioral analysis |

| VR/AR for Technique Visualization | 45% improvement in exercise technique with augmented reality features | Emerging tech studies |

These new tools help companies watch their equipment and know when repairs are needed. They also help keep users safe. AI systems make workouts better and lower the number of accidents. Blockchain keeps data safe, which is important for most users. VR and AR help people do exercises with better form, improving technique by 45%.

Risk Management

Supply chain management in 2025 has many risks. Economic risks include suppliers going out of business and prices rising. Environmental risks like storms and climate change can stop deliveries. Political risks, such as new trade rules or unstable governments, make things less certain. Ethical risks come from how materials are bought. Cybersecurity threats attack digital systems. These risks can make it hard to find workers and keep the supply chain working.

Companies that prepare well can keep working during tough times. They use different ways to handle risks:

- Use many suppliers so they do not depend on just one place.

- Move some production closer to home to avoid political problems.

- Spend money on AI and new tech to predict problems and plan better.

- Use contracts that change with shipping prices.

- Keep extra important materials in stock.

- Watch the supply chain in real time and use data to decide what to do.

- Make buying plans flexible with short contracts and different ways to ship.

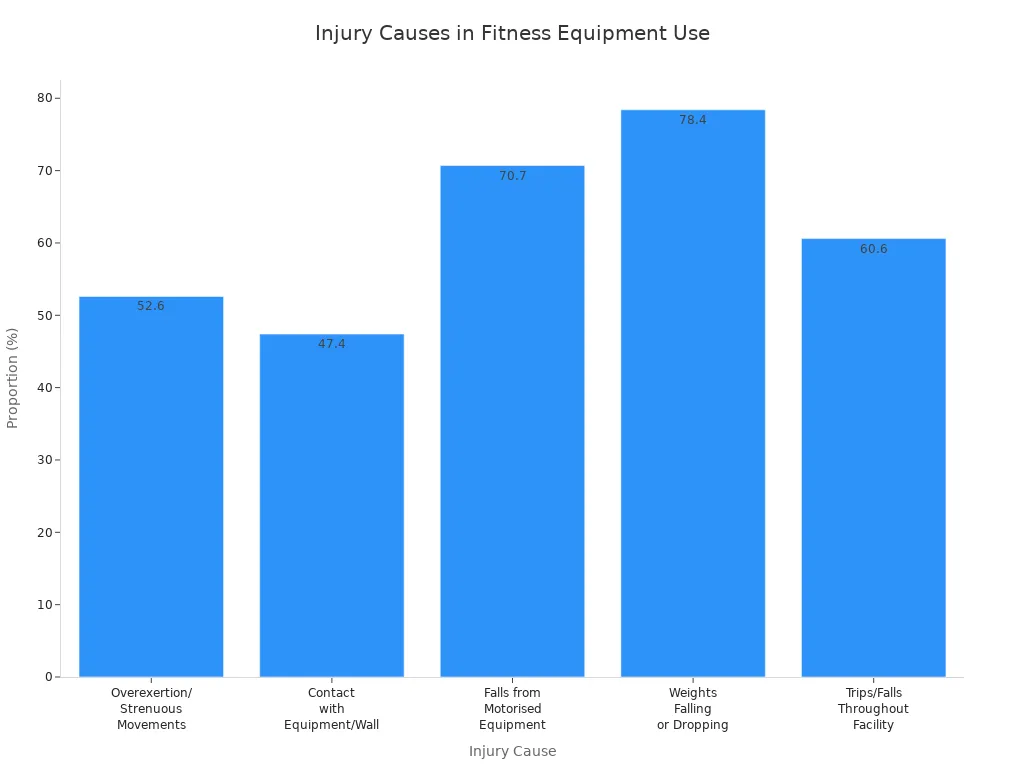

These ideas help companies avoid problems and keep working well. Real injury numbers show why risk management is needed. Overexertion causes more than half of free weight injuries and over a third in group classes. Most treadmill injuries happen because people fall. This shows why safety features and teaching users are important. Storing and handling dumbbells safely stops most injuries.

| Injury Cause | Frequency/Proportion | Implication for Risk Management |

|---|---|---|

| Overexertion/Strenuous Movements | Highest in free weights (52.6%) and group classes (35.9%) | Training and monitoring prevent strain-related injuries. |

| Contact with Equipment/Wall | Common in boxing activities (47.4%) | Equipment placement and protective measures are important. |

| Falls from Motorised Equipment | Majority of treadmill injuries (70.7%) | Safety features and user education reduce risk. |

| Weights Falling or Dropping | Most dumbbell injuries (78.4%) | Secure handling and storage protocols are essential. |

| Trips/Falls Throughout Facility | Over half unspecified (60.6%) | Facility design improvements and hazard identification reduce falls. |

| Hospitalizations | 8% of ED presentations | Focused prevention efforts are needed for severe injuries. |

By knowing these risks and using the right plans, companies can make things safer and lower injury rates. Good supply chain management helps fitness equipment get to customers safely and on time, even when things are complicated around the world.

Gym Equipment Supply Chain Challenges

Raw Material Shortages

Raw material shortages make big problems for the gym equipment supply chain. When there are not enough materials, factories slow down or stop. This means it takes longer to make gym equipment. Companies lose money because they cannot sell as much. They might have to pay extra fees or get in trouble with contracts. Customers get upset when their orders are late again and again. This makes it hard for companies to keep good relationships with buyers. To fix these problems, companies work on better inventory management and planning. They try to get supplies from more than one place. Some companies make special teams to solve problems fast. They look for new suppliers and change their work schedules. If they run out of one part, they use another if possible. Digital tools help workers see what is happening right now. This helps them make smart choices and avoid big slowdowns. These ideas help companies keep making gym equipment without big stops.

- Not enough materials slows down work and costs more.

- Customers lose trust if orders are late many times.

- Better planning and more suppliers help stop slowdowns.

- Real-time data helps people make quick choices.

Demand Fluctuations

The need for fitness equipment changes a lot and very fast. Around New Year, more people want gym equipment, so demand goes up. Sometimes, a trend or a famous person can make everyone want something new. If people have less money or something big happens in the world, demand can drop. Other companies’ sales and ads also change what people buy. All these things make it hard to guess how much to make. Companies might not have enough products or have too many. This can cost more money and mess up work plans. When factories rush, quality can go down. Using AI and real-time data helps companies guess better. They can see what is happening and change plans fast. Having more suppliers and using blockchain helps them see and fix problems quickly.

- Trends and seasons make demand hard to predict.

- Too little or too much stock causes problems.

- AI and data help companies plan better.

- Flexible supply chains help with busy times.

Regulatory Compliance

Rules and laws affect every step of the gym equipment supply chain. In the U.S., companies must test products and follow safety rules. They need to label things right and report to groups like the CPSC. Gyms must follow OSHA rules for safe buildings and equipment checks. In the EU, companies must check for risks and keep records. They must show who made the product and keep track of safety problems. Importers and sellers must make sure products are safe and help with recalls. These rules make sure gym equipment is safe and works well from the factory to the customer.

- U.S. rules need safety tests, labels, and checks.

- EU rules need risk checks, records, and safety plans.

- Following rules keeps people safe and equipment ready.

Smart Supplier Sourcing

Digital Vetting Tools

Picking good suppliers for fitness equipment needs a clear plan. Companies use digital vetting tools to check suppliers fast and well. Veridion is a top platform with a big database. It has information on over 120 million companies. This tool shows company size, online presence, industry, insurance, technology, products, and sustainability. Their Supplier Discovery service uses natural language search. This makes it simple to find suppliers that fit special needs.

A set vetting process keeps things fair for everyone. Companies use the same rules for all suppliers. This helps make sure things are equal. Checking certifications is very important. Tools like IAF CertSearch help companies check certifications like ISO 9001 and sustainability. This step proves suppliers meet quality and ethical rules.

Looking at production skills is also important. Companies check if suppliers have enough space, workers, and transport. These checks show if suppliers can deliver on time and in large amounts. Quality audits, like visits and checking samples, protect the brand. Jim Kennemer, who started Cosmo Sourcing, says to get product samples to avoid bad defects.

| Vetting Step | Purpose | Example Tool/Method |

|---|---|---|

| Supplier Intelligence | Gather company data | Veridion |

| Certification Verification | Confirm quality and compliance | IAF CertSearch |

| Production Assessment | Check capacity and scalability | Site visits, digital forms |

| Quality Audits | Ensure product standards | Sample evaluation |

Tip: Companies can trust suppliers more by using digital vetting tools and keeping the vetting process the same.

Supplier Diversification

Supplier diversification makes the fitness equipment supply chain stronger. Companies lower risk by using many suppliers, not just one. This plan helps avoid problems from trade issues or trouble in one area. The “China + 1” plan adds suppliers from other places. This helps during big events like pandemics or conflicts.

Diversification helps lower risks. Companies add backup suppliers and make strong partnerships. They also watch suppliers closely. These steps help keep the supply chain working. Good data skills and technology help track supplier work and market changes. Companies use this data to change plans fast when needed.

- Supplier diversification stops supply chain problems.

- Strong partnerships and backups keep equipment moving.

- Technology helps watch suppliers and market changes.

Note: Companies that use many suppliers and technology to watch them have a stronger fitness equipment supply chain.

Shipping and Logistics Optimization

Shipping and logistics are very important in the fitness equipment industry. Companies move big, heavy products quickly and safely. They must deliver fast and install equipment carefully. Smart strategies help save money and avoid delays. These ideas also keep customers happy. The next parts show how real-time tracking, cross-dock solutions, and last-mile delivery make shipping better for fitness equipment.

Real-Time Tracking

Real-time tracking lets companies see where shipments are. GPS trackers, RFID tags, and sensors give updates on location and condition. This helps companies find delays and fix problems early. IoT devices check temperature and vibration to stop damage. Real-time data helps companies change routes fast and save fuel.

- Companies use real-time tracking to:

- Make delivery routes better and use less fuel.

- Watch inventory and stop running out or having too much.

- Share info with suppliers, carriers, and stores on one platform.

- Make quick choices to stop delays.

- Keep products safe by checking shipment conditions.

AI tools help even more. They guess demand and help companies change supply chains. This makes work smoother and costs lower. Customers get faster shipping and better updates about their orders.

Real-time tracking helps customers trust companies. They always know where their equipment is.

Cross-Dock Solutions

Cross-dock solutions help move fitness equipment without long storage. Shipments go to a central place and then straight to trucks. This lowers storage costs and makes delivery faster.

Benefits of cross-docking for fitness equipment:

- Ships big and expensive items faster.

- Cuts storage and worker costs.

- Less chance of too much stock and lower inventory.

- Central operations help plan loads better.

- Less damage because there are fewer handling steps.

Challenges of cross-docking:

- Timing must be perfect or delays happen.

- Needs special buildings and automation, which cost a lot.

- Must guess demand well to avoid running out.

- Suppliers, carriers, and workers must work together closely.

Companies that use smart scheduling and new tech like warehouse systems and RFID do better. They cut lead times and give better service. Good planning makes cross-docking change shipping for fitness equipment.

| Benefit | Description |

|---|---|

| Faster Shipping | Delivers big equipment quicker |

| Cost Reduction | Saves money on storage and workers |

| Lower Inventory | Keeps less money tied up in stock |

| Centralized Operations | Plans loads and routes better |

| Reduced Damage | Fewer steps protect equipment |

Last-Mile Delivery

Last-mile delivery is the last step before customers get their equipment. It brings fitness equipment from the warehouse to the customer’s home. This step shapes how customers feel about the company.

New ideas make last-mile delivery quicker and more reliable. Route software saves fuel and cuts pollution. Electric vehicles and bikes help deliver in busy cities and are better for the planet. Micro-centers keep inventory close to customers and make delivery faster.

Companies now offer special services like white glove delivery. This means they handle, set up, and clean up after installing equipment. These services are important for big, complicated fitness equipment. Checking quality before delivery stops returns and keeps customers happy.

- Key last-mile delivery strategies:

- Use route software to work faster.

- Give choices like lockers or scheduled times.

- Give real-time updates and clear communication.

- Use green packaging and eco-friendly vehicles.

- Deliver and set up equipment with trained teams.

“Last-mile delivery is now a big part of the brand experience. Speed, real-time updates, and being green are now expected. Delivery is the new shopfront for online shopping.”\

— Michael Giannulis, CEO of Lead Engine Labs

Customers want fast, flexible, and clear delivery. Companies that do this get happier customers and more repeat sales. Good logistics and careful setup make sure fitness equipment arrives safe and works well.

Actionable strategies for optimizing shipping and logistics:

- Get instant quotes from many carriers and use smart routing.

- Automate customs and paperwork for shipping to other countries.

- Build local warehouses to cut delivery delays by half.

- Use AI to guess demand and match production and supply.

- Use lean manufacturing and modular designs to fill orders faster.

- Add digital payments and trade financing to help cash flow.

Making shipping and logistics better needs technology, planning, and caring about customers. Companies that do this have a strong advantage in the fitness equipment market.

Payments and Financing

Digital Payment Platforms

Digital payment platforms make buying and selling easier in 2025. These platforms let companies pay quickly and safely. Buyers and suppliers use digital wallets and banking apps. Payment gateways help process orders fast. These tools cut down on paperwork and save time. Many platforms work with different currencies. This helps global companies avoid waiting for money changes.

Payment automation helps companies manage their money better. They can track bills and set reminders to pay on time. This lowers the chance of late payments. Fraud detection keeps payments safe from bad transactions. Digital records help with audits and rule checks. Fitness equipment stores get updates on payments right away. This helps them keep track of stock and plan what to buy next.

Companies using digital payment tools do better than others. They build trust by making payments safe and easy for everyone.

Bulk Purchasing Benefits

Bulk purchasing saves gym equipment sellers and buyers a lot of money. Buying many items at once lowers the cost for each piece. This skips retail markups and can cut prices by up to 70%. Suppliers give extra deals for buying in bulk. They offer discounts and special packages.

- Buying in bulk lowers costs for each item.

- Extra deals and discounts save more money.

- Tax rules like Section 179 help save on taxes.

- Shipping costs go down when items are sent together.

- New gym owners make money back faster with cheaper equipment.

- Owners can change or sell equipment as they want.

- Financing and payment plans help small businesses buy more.

Bulk buying lets gym owners pick what equipment they want. They can also sell items they do not need. Many suppliers offer payment plans so small gyms can buy in bulk. This helps companies grow and stay strong in the fitness business.

Digital Platforms and Automation

AI and IoT Integration

AI and IoT have changed how companies run their supply chains. These tools help companies watch equipment and inventory all the time. Sensors on fitness equipment send updates about where things are and if they are working. AI uses this information to guess when machines need fixing or when supplies are low. This helps companies stop delays and keep making products.

Companies use AI to check how well suppliers are doing. They can find problems early. For example, line-item tracking and ETA updates help managers change plans before things get worse. Predictive analytics help companies guess how much equipment people will want. This means teams know how much to make. It helps stop running out of stock and makes customers happier.

| AI Monitoring Feature | Impact on Supply Chain | Business Benefit |

|---|---|---|

| Line-Item Tracking | Finds problems early | Fixes issues faster |

| ETA Updates | Changes schedules | Plans production better |

| Supplier Performance Tracking | Spots risks sooner | Builds better supplier relationships |

| Inventory Monitoring | Stops running out of stock | Keeps production steady |

AI and IoT help companies make smarter choices and keep the supply chain strong.

Automated Workflows

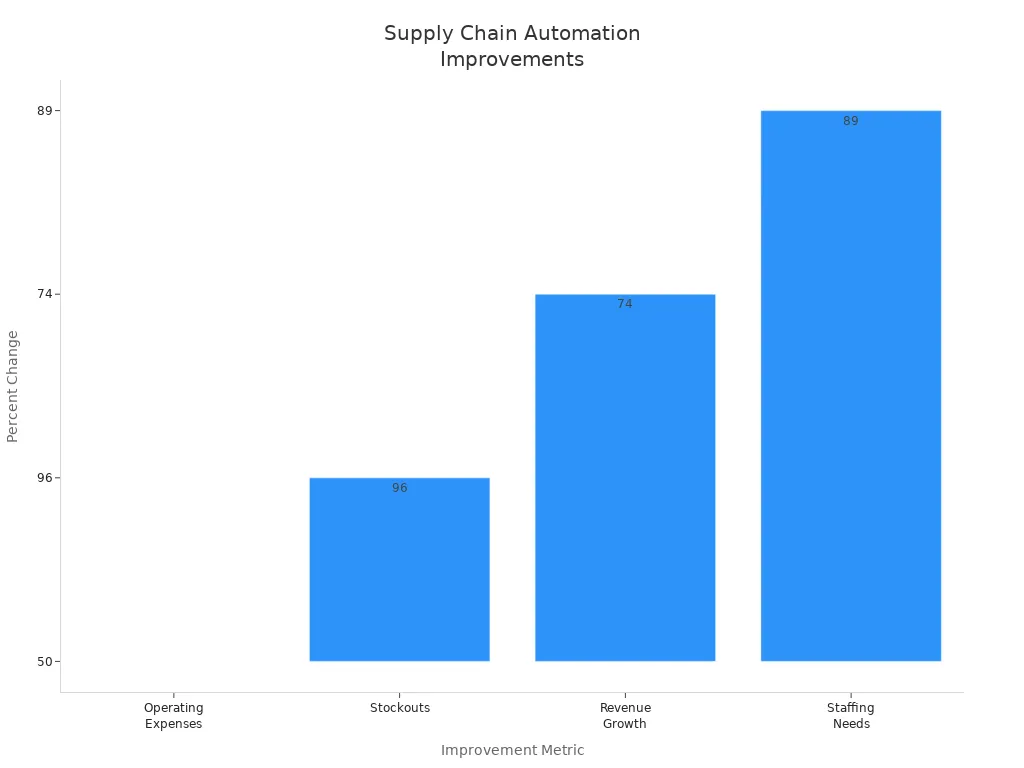

Automated workflows make supply chains work faster and better. Companies use software to handle orders, shipping, and checking inventory. Automation means people do less manual work and make fewer mistakes. This leads to fewer delays and saves money.

After using automation, companies saw big changes:

| Improvement Metric | Measurable Result | Business Impact |

|---|---|---|

| Operating Expenses | Up to 50% less | Saves a lot of money |

| Stockouts | 96% fewer times out of stock | More products ready for customers |

| Revenue Growth | 74% more in 3 months | Makes more money with better inventory |

| Staffing Needs | 89% fewer workers needed | Gets more done with fewer people |

| Supplier Performance | Better OTIF delivery | Works better with suppliers |

Automated workflows let teams focus on making good products and new ideas. Companies keep the right amount of inventory and react fast when things change. Automation gives fitness equipment suppliers a big advantage in a busy market.

Building Resilient Networks

Supplier Diversification

Supplier diversification is a smart way to make supply chains stronger in fitness equipment. If a company uses only one supplier, it can have big problems if something goes wrong. Using many suppliers from different places helps companies avoid trouble from things like bad weather or political issues. During COVID-19, some companies helped their suppliers with shipping and flexible deals. This made it easier to get products. Fitness equipment companies can do the same. If one supplier is slow, others can keep things moving. Working with suppliers in different places helps with costs and rules. Digital tools help companies watch how suppliers are doing. They can change plans fast if needed. These steps help companies keep making gym equipment without big stops.

- Using more suppliers lowers risk from problems.

- Flexible shipping helps change delivery routes fast.

- Good partnerships with suppliers help during tough times.

- Strong computer systems show what is happening right now.

Companies that use many suppliers and help them build supply chains that are strong and quick to change.

Sustainable Practices

Sustainable practices are now very important for fitness equipment supply chains. Companies pick suppliers who care about the environment. They check things like pollution, worker safety, and how much waste is made. Many companies use recycled materials and less packaging to cut waste. Green shipping, like using trucks that save fuel, helps lower pollution and costs. IoT and blockchain help companies watch how green their supply chain is. Training workers teaches them to use eco-friendly ways.

- Pick suppliers who follow green rules.

- Cut waste by reusing and recycling.

- Use green shipping and better delivery routes.

- Digital tools help see how green the supply chain is.

- Teach workers to use eco-friendly methods.

These actions help companies lower pollution by up to 40%. They also waste less and work better. Being open about green actions helps customers trust the company. Using sustainable practices makes the brand look good and helps keep making fitness equipment for a long time.

Case Studies

Industry Success Stories

Precor is a leader in fitness equipment because it manages its supply chain well. The company stopped using short-term sourcing and started working with suppliers around the world. This helped Precor keep less inventory and spend less money storing products. Precor uses IT systems like SAP to make sourcing and inventory easier. Their system works almost perfectly and helps keep production going and products high quality. Precor also started making some products in its own factories. This saved money and gave Precor more control over how things are made. When Precor launched the TRM14 treadmill, it increased production from 60 to 170 units each day in only 80 days. Precor planned how much to make and worked closely with suppliers to grow fast. The company also used smart buying methods to get services and handle shipping better. These steps helped Precor create new products and react quickly when the market changed.

ICON Fitness teamed up with NonstopDelivery to make last-mile delivery better. NonstopDelivery changed its services to fit what ICON needed. This cut down on waste and made deliveries faster. ICON got products to customers on time and without mistakes. The partnership shows that special delivery plans can help fitness equipment companies work better.

Lessons from Disruptions

- Companies found that being flexible and using many suppliers helps stop problems.

- Getting supplies locally makes delivery faster and costs less.

- Using data and just-in-time methods helps manage inventory.

- Checking quality often keeps the brand strong.

- New technology and air shipping make deliveries more dependable.

- Talking with suppliers and making long contracts helps keep things steady.

- Peloton used more air shipping and added suppliers to avoid delays and keep customers happy.

- Core Health & Fitness worked with Redwood Logistics to see the whole supply chain and saved almost 9% on shipping.

- Future plans will focus on being strong, selling online, and being green.

- Companies that change routes, suppliers, and shipping quickly do better when things go wrong.

- Planning for risks and thinking ahead helps companies get ready for problems.

- Protecting digital systems is important as supply chains use more technology.

- Carriers without their own trucks or warehouses stay strong by being flexible and creative.

Smart supply chain management for fitness equipment uses new technology and strong networks. Companies that use smart tools do better and work well with suppliers.

- Technology helps companies work together and connect their systems.

- Companies should share information and move materials in the best way.

- Always trying to get better helps all companies keep up.

Studies show that using digital tools lowers risks and helps companies do well. Leaders should look at what they do now and spend money on new technology to keep winning.

FAQ

What technologies help manage fitness equipment supply chains in 2025?

AI, IoT, and blockchain are the main tools. They help companies watch shipments and guess what people will buy. These tools also keep data safe. Companies use them to make work faster and safer at every step.

How do companies handle raw material shortages?

Companies use more than one supplier and keep extra materials. Digital tools help them check inventory all the time. Teams move fast to find new suppliers or change work plans when they run low.

Why is last-mile delivery important for fitness equipment?

Last-mile delivery affects how happy customers are. Fast and careful delivery makes sure equipment gets there safely. Companies use route software and trained workers to do this job better.

What makes a supply chain resilient?

Using many suppliers and watching things in real time helps. Flexible shipping plans also make supply chains stronger. Companies use green methods and digital tools to handle problems quickly.

How do digital payment platforms benefit the supply chain?

Digital payment platforms make paying faster and cut mistakes. They help with payments from other countries and track spending. This helps companies work better with suppliers and run smoothly.